System descprition Omniflex®

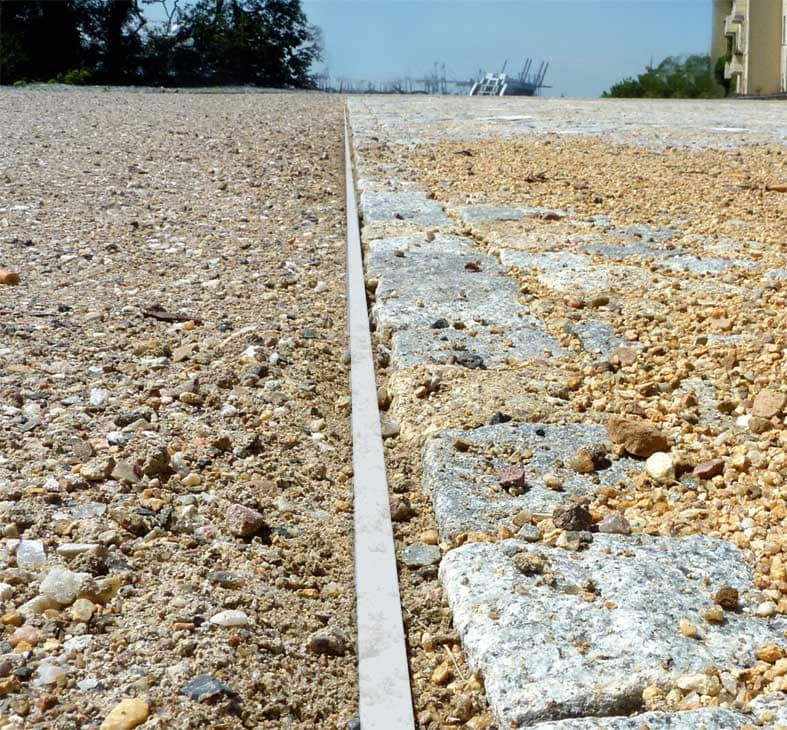

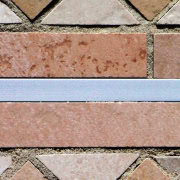

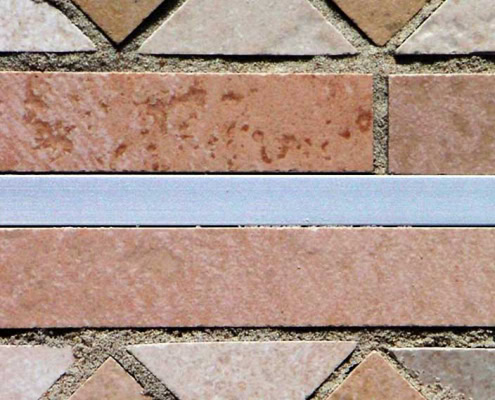

The Omniflex® path and paving profile is designed for many different areas of application and combines the highest standards of design, quality and stability. It provides terrace and paving slabs, stone paving, gravel, crushed stone and asphalt with the necessary support, prevents the outer base layer from giving way and facilitates the design and construction of your outdoor and indoor areas.

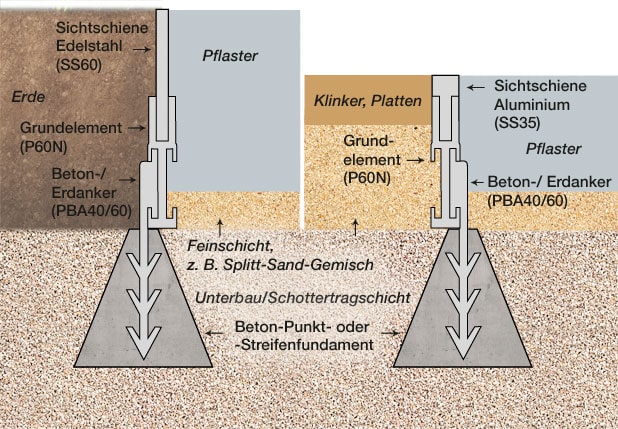

The basic elements made from an aluminium alloy are completed by visible rails made from natural aluminium, anodised aluminium (silver or dark bronze) or high-quality stainless steel. Various anchoring solutions means that the profiles can be mounted onto solid ground, flat roofs, concrete or gravel bases, as well as installed in the ground and in concrete bases.

The very stable edging profiles can be shaped into arcs and curves easily on site and without special tools. The system is extremely robust despite its relatively low weight.

The different visible rail designs provide many different design options. This allows design elements to be integrated into ground coverings, paths and parking areas can be visibly marked and covering separations and borders can be created.

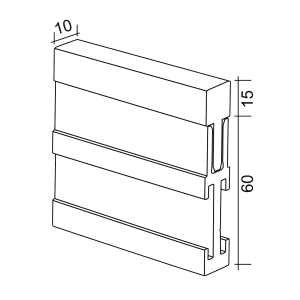

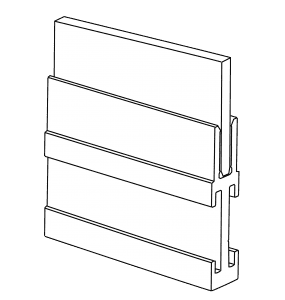

The basic elements and visible rails are connected with each other with a notch and spring system. It can be assembled on site or in the factory.

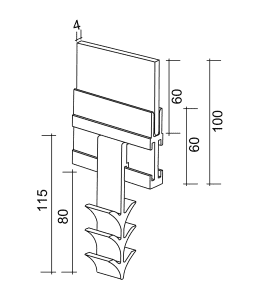

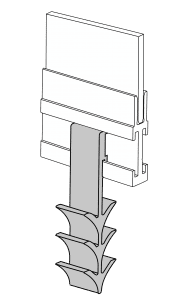

The anchoring can be carried out either with 90° profile anchors with punched holes for steel nails or screws, with special concrete and ground anchors anodised for a high level of corrosion protection.

The combination of high quality and virtually corrosion-resistant materials and the individually adjustable visible rails and anchoring options make this path and paving border so unique.

Your advantages at a glance:

- Clean lines and contours

- Easy to transport and easy laying

- Reusable, corrosion-resistant and recyclable aluminium alloy

- Malleable for the individual design of arcs, circles and free forms – without tools

- Basic element for the two-sided mounting of different anchoring options and various visible rails

- Visible rails in different colours provide various design options

- Moveable and therefore individually adjustable 90° profile anchors with holes for steel nails or screws

- Moveable and therefore individually adjustable concrete and ground anchors with anodised surface hardening for excellent corrosion protection underground.

- The basic elements with visible rails can be pre-assembled in the factory on request

Installation Notes Omniflex®

- The profiles (base elements P60N and visible rails SS35/60) are usually installed in such a way that the upper edge of the visible rails sit flush with the surface to be created later. The special profile shape allows the number and position of the anchoring elements to be adjusted to the relevant building project and the surface being built on. Radii can be formed starting at approx. 4 m.

- The visible rails can be hammered into the grooves of the base elements using a plastic mallet before commencing installation. Depending on the structural conditions, the visible rails can also be installed after the installation of the base elements. It is important to ensure here that the intake groove, which is required for the visible rails and clamp rails, doesn’t become constricted. This can be achieved by inserting 3.5-mm-thick cardboard, plastic, wood, etc., which must then be removed after installation of the rails.

- The profiles can be quickly and easily cut to length with a conventional hacksaw as needed. Care should be taken to ensure a clean cut in the area of the guide rail and the visible rail.

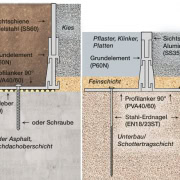

Installation variants with concrete and ground anchors

Method A

- The concrete/ground anchors (PBA40/60) are inserted into the guide rails of the base elements. Depending on the planned radii and other structural conditions, you should use approx. 4 concrete/ground anchors per running metre. Offset arrangement is possible.

- The anchors inserted into the base elements are pressed into the cement, as far as the marking bulge, while it is setting and still soft. After that they can be aligned horizontally, if necessary.

- Once the cement has set, the visible rails are hammered into the grooves of the base elements using a plastic mallet, if this hasn’t been done yet. When installing the visible rails on site, the base elements can be additionally fixed to each other by installing the visible rails with an offset of approx. 50 mm.

- The next step is to add and, if necessary, lightly vibrate the fine layer before installing the base layer or surface.

Method B

- The concrete/ground anchors (PBA40/60) can also be installed after vibration of the base layer, before the installation of the base layer or, if applicable, before the vibration of the (paved) surface. When using this method, bear in mind that the vibration can cause the base layer/surface to sink.

- A recess (approx. 10 cm deep and 5 cm wide) is created in the base layer at the points where the anchors are pre-installed in the base elements. A large chisel may work well for this. The base elements are then adjusted so that the anchors are positioned in the base layer. The anchors are then embedded with a concrete-cement mixture.

- If the profile is to be laid on a surface which has already been paved, it is best to insert the concrete/ground anchors on one side and not offset.

- The next step is to add the fine layer and install the base layer respectively surface. If vibration is necessary, take care not to damage the visible rails.

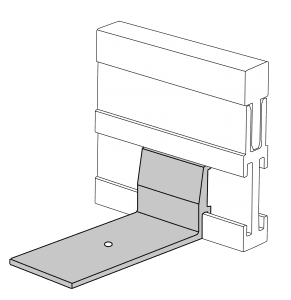

Installation variant with 90 ° profile anchor

- The profile anchors (PVA40/60) are inserted laterally into the guide rails of the base elements. Depending on the surface and the shape of the profile, around 5 anchors should be used per running metre. The profile, along with the profile anchors, is then laid down on the flat surface, the lower base layer, according to the construction plan in terms of shape and length.

- Depending on the application and the surface, the profile anchors can also be arranged offset on both sides. Installation is carried out with steel stakes (EN18/23) in the base layer, with screws and dowels in the concrete foundations or with special glue (WFB310) on smooth, solid, dust-free substructures.

- The visible rails are then hammered into the grooves of the base elements using a plastic mallet, if this hasn’t been done yet. When installing the visible rails on site, the base elements can be additionally fixed to each other by installing the visible rails with an offset of approx. 50 mm.

- In order to achieve a satisfactory result, the entire installation should be carried out in a careful, precise manner.

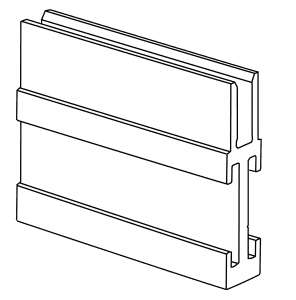

Basic element

Natural aluminium

- L = 500 mm, H = 60 mm | P60N05

- L = 1.000 mm, H = 60 mm | P60N10

- L = 2.000 mm, H = 60 mm | P60N20

- L = 2.500 mm, H = 60 mm | P60N25

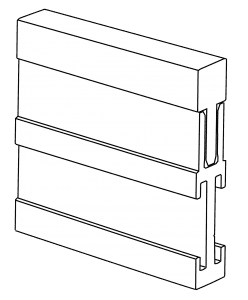

View rail

Stainless steel V2A, 40 mm visible

- L = 500 mm, H = 60 mm, d = 4 mm | SS60VA05

- L = 1.000 mm, H = 60 mm, d = 4 mm | SS60VA10

- L = 2.000 mm, H = 60 mm, d = 4 mm | SS60VA20

- L = 2.500 mm, H = 60 mm, d = 4 mm | SS60VA25

View rail

Natural aluminium, 15 mm visible

- L = 500 mm, H = 35 mm, d = 10 mm | SS35N05

- L = 1.000 mm, H = 35 mm, d = 10 mm | SS35N10

- L = 2.000 mm, H = 35 mm, d = 10 mm | SS35N20

- L = 2.500 mm, H = 35 mm, d = 10 mm | SS35N25

View rail

Aluminum silver anodized, E6 / EV1, 15 mm visible

- L = 500 mm, H = 35 mm, d = 10 mm | SS35E05s

- L = 1.000 mm, H = 35 mm, d = 10 mm | SS35E10s

- L = 2.000 mm, H = 35 mm, d = 10 mm | SS35E20s

- L = 2.500 mm, H = 35 mm, d = 10 mm | SS35E25s

View rail

Aluminum dark bronze anodized, E6 / C34,15 mm visible

- L = 500 mm, H = 35 mm, d = 10 mm | SS35E05b

- L = 1.000 mm, H = 35 mm, d = 10 mm | SS35E10b

- L = 2.000 mm, H = 35 mm, d = 10 mm | SS35E20b

- L = 2.500 mm, H = 35 mm, d = 10 mm | SS35E25b

90 ° Profile anchor

Aluminium

- B = 40 mm, H = 35 mm | PVA40

- B = 60 mm, H = 35 mm | PVA60

round hole Ø = 7,5 mm

Concrete and ground anchors

Anodised aluminum, E6 / EV1

- B = 40 mm, H = 35 mm + 80 mm (Einbautiefe) | PBA40

- B = 60 mm, H = 35 mm + 80 mm (Einbautiefe) | PBA60

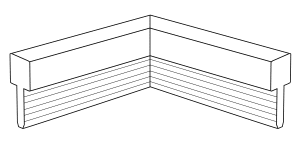

Corner element 90 °

250 mm + 250 mm

- (Visible rail without basic element) stainless steel | EV60VA25

- Aluminium natural | EV35N25

- Aluminium silver anodized, E6 / EV1 | EV35E25s

- aluminum dark bronze anodized, E6 / C34 | EV35E25b

Steel earth nail

galvanized for PVA40 / 60 (content 50 pieces)

- L = 180 mm, Ø = 6 mm | EN18ST

- L = 230 mm, Ø = 6 mm | EN23ST

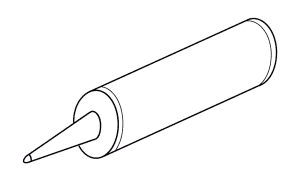

Special adhesives

1-component special adhesive, 310 ml content | WFB310

(for adhesive mounting of PVAxx on clean surfaces as well as the visible rail

Stainless steel SS60VA in the basic element P60Nxx)